What is Eau-de-Vie?

The simple answer is, translated from French, it means brandy.

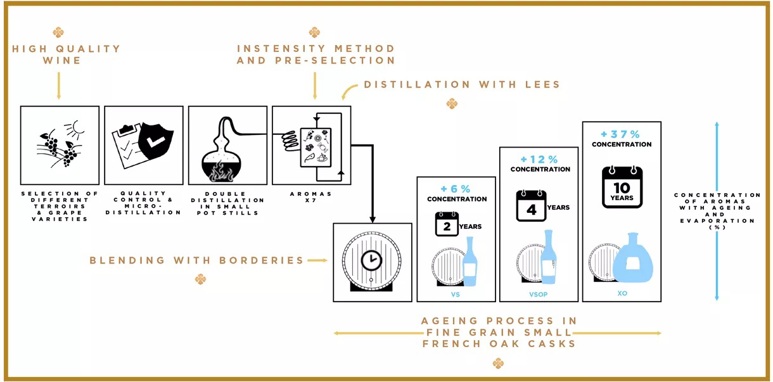

Cognac is produced using specific grapes that are natively grown in the cognac region. Although the grapes used for cognac are undrinkable as wine, they yield excellent results when distilled and aged.

Cognac only uses white grapes and a “cru” cognac must not contain less than 90% of the following varieties:

- Ugni Blanc: A high-yield grape also known as Saint-Emilion or Trebbiano.

- Folle Blanche: Susceptible to disease and sometimes referred to as picpoule, gros plant, and enrageant blanc.

- Colombard: An offspring of Chenin blanc and Gouais blanc wine grapes that is occasionally used for Bordeaux and Goscony wines.

Meanwhile, the following grapes can only account for up to 10% of a “cru” cognac:

- Follignan: A complex grape produced by crossing Ugni Blanc and Folle Blanche.

- Jurançon Blanc: Known to produce average or low-quality wines.

- Meslier St-François: Another Guoais and Chenin crossing that originated in the Loire valley.

- Sélect: An “accessory” grape for producing cognac.

- Montils: A rarer grape that was nearly lost to phylloxera.

- Sémillon: Usually used for producing sweet “moelleux” Sauternes and Barsac wines.

Cognac is a large appellation region, which is divided into smaller “cru” zones. If a cognac wishes to be designated as a cru from one of these zones, it must abide by the specific concentrations. However, cognac labels choosing not to carry a cru name have a much greater level of flexibility when blending their creations.

And as mentioned above, it is what is created from the double distillation of the wine but it is far less in quantity and much more concentrated than the original wine.

The eau-de-vie, at this moment, is completely clear, it has a fantastic aroma, reminding us of vineyards after the rain, a sharp taste, and alcohol content of about seventy percent. It is this eau-de-vie, the end product of distillation, that is put into wooden casks.

In short, cognac is simply a variety of brandy that is named after a town in the Charente department of France. However, cognac is produced throughout much of the Nouvelle-Aquitaine region that surrounds it.

As you will learn in this guide on how cognac is made, its production follows a strictly regulated process as the brandy falls under a number of French appellations. Interestingly, the cognac-producing region is divided into several zones, which may each have their own appellations too.

As a brandy, cognac is made by distilling wine, which is then aged for a number of years in oak casks. All of the grapes are grown locally and some of the varieties may sometimes be used for making Bordeaux wine, too.

In France, the resulting distillates for making cognac are regarded as eau-de-vie and in some regions, eau-de-vie is enjoyed unaged. However, all cognac must be aged for at least two years in oak barrels.

Similarly, the barrels can only be made from French oak, which usually comes from the Limousin or Tronçais forests.

The aging process of cognac takes place in these oak barrels over many years. An important moment in the aging of cognac arrives sometime between five and eight years in the cask. The most noticeable results are in the aromas, in the flavor of vanilla that has become a fixture, and the color that has intensified, but the palate still needs more time in the cask.

It is during the next few years that the true character of cognac flourishes. The complexity of floral and fruity aromas develops, the color gets deeper and the taste becomes a real pleasure. When the cognac gets past its twenties, a noticeable change in taste becomes apparent as a result of the further breakdown of tannin, giving it a touch of natural sweetness.

One of the ‘rules’ for making cognac is the type of oak used to make these aging barrels. This can be one of only two types, Limousin or Tronçais. Limousin oak comes from the forests of the same-named region in Southwest France and similarly, Tronçais oak comes from the forests in Tronçais, near Burgundy.

There’s one major difference between these two types of oak and that’s that Limousin oak has much wider grains compared to its Tronçais cousin. This allows the liquid within to penetrate the oak further and consequently, the aging process happens more quickly. Of course, the word ‘quickly’ has to be taken into context, because when it comes to cognac, nothing happens fast. Another important point to note is that when a barrel is first made, it undergoes a process known as toasting or ‘bousinage’, a procedure that literally chars the wood. This can be carried out to a greater or lesser extent and is done to remove any harmful tannins in the wood.

The casks that are used for Lambay Irish Whiskey is the Master Cellar's secret but will always derive from French oak, with several years of rich aromatic intensity absorbed into the wood.

The casks are specially prepared to hold our delicate distillates cautious that the grape mixes with the grain in this case and that is an act of infinite balance to secure the signature taste in all our whiskeys.